|

|

|

|

RAISING

THE SPEED LIMIT

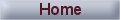

4 Station #5000CS

|

| |

PRODUCT SPECIFICATIONS

5000CS Series

Dimensions: 122" L x 20" W x 44" H

Max Blind Size: 108"

Weight: 500-600 lbs.

Power Supply: 110V (adaptable to International requirements)

Rout: .75" X .125" Standard. Custom sizes

available

|

Available Models

|

#5000ACS 2

Station Rack & Pinion - Punch Only |

|

#5000CS 4

Station Rack & Pinion - Punch Only |

|

#5500CS 5

Station Rack & Pinion - Punch Only |

|

#5550CS 5

Station Rack & Pinion - 4 Punch/ 1 PVC Double Radius Cut Off |

|

#5600CS 6

Station Rack & Pinion - 4 Punch/ 2 PVC Single Radius Cut Offs |

Custom Configurations available on all models

Team B & B Electric Machinery has earned a reputation for SPEED and

DURABILITY. The 5000CS Series has the EXPANDABILITY to be upgraded

into a fully automated machine. Specialty dies give the machine

the FLEXIBILITY to fabricate a wide range of materials, shapes and sizes. The

rack and pinion system promotes ACCURACY, enhances EFFICIENCY and increases

PRODUCTIVITY. These key factors contribute to PROFITABILITY and

are essential to any successful horizontal blind manufacturer.

Key Benefits

|

Upgradeable

to Fully Automatic |

|

High

Speed 110V Electric |

|

30%

More Blinds Per Shift |

|

Crank

Operated Rack & Pinion System |

|

Significantly

Reduced Set Up Time |

|

Sound & Secure

Lock-Down Stations |

|

Precise

Head Rail Index System |

|

Standard

108" Wide Blind Capacity |

|

Rout

Hole Waste Collection System |

|

Electric

Auto Activation Switch |

|

|

2-6

Routs & Cut Off Configurations |

|

Routs

Slats from 1" to 3" |

|

Wood,

Foam, PVC & Composite |

|

Exclusive

Quick--Change Dies |

|

Specialty

Die Configurations |

|

Custom

Dies Available |

|

Control

Box With Counter |

|

Sloped

Slat Supports |

|

Dual

Level Slat Trays |

|

1

Year Factory Warranty |

|

|

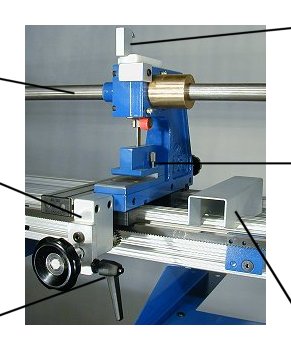

Shaft Driven

The Keyed Steel Shaft delivers power and synchronization while

the Brass Alignment sleeves provide the Cast Stations unmatched

stability and ease of movement.

|

|

Head Rail

Index System

The Head Rail Index System allows the punched Head Rail to Act

as the template for setting up the punch stations. The 90*

index pointers make precision alignment Fast, Easy and Accurate

|

|

Rack & Pinion

System

This B & B exclusive System provides the fastest and most precise

station positioning, reducing set up time by 30%. Moving

stations is no longer a difficult task and operator error is virtually

eliminated.

|

Quick Change

Dies

The addition of steel guide pins located in the station base guarantees

precise die location without further adjustments. Once the

die is locked in place, simply insert the unique B & B Magnetic

Punch pins.

|

|

Quick-Lock/Release

Once in position the Lever Activated Locks secure the station to

eliminate movement while the slats are routed.

|

Slat Supports

Non-Marking coated aluminum support ramps, guide the slats throughout

the punching process.

|

Copyright © 2005 Team B & B

Last modified: February 17, 2005

|

|